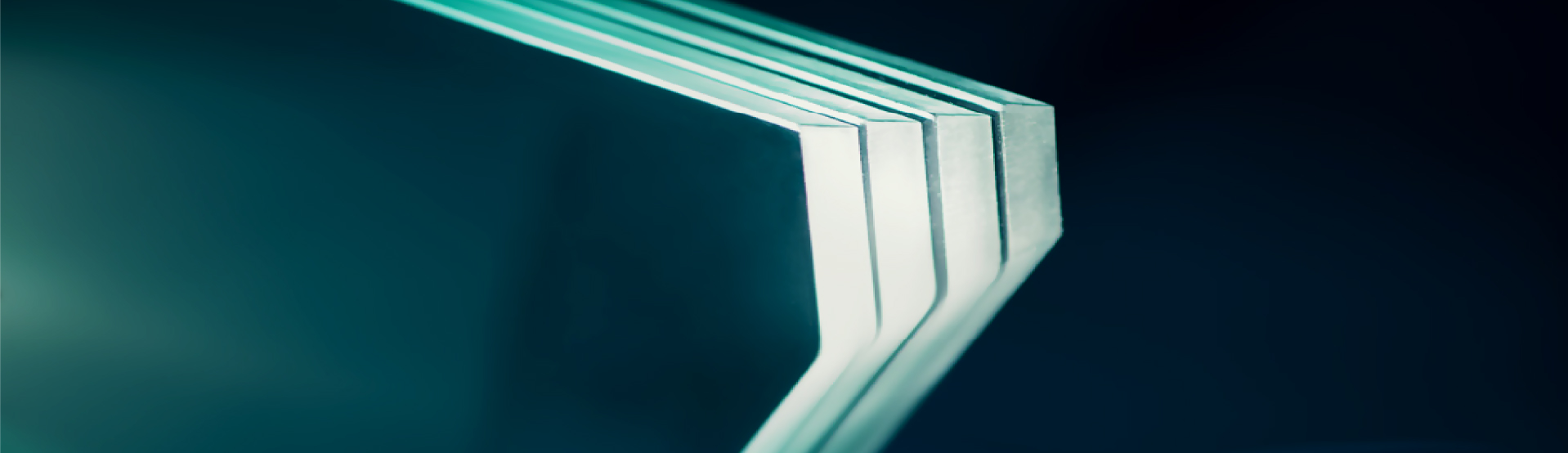

AGP sGlass

The No. 1 supplier of transparent armor worldwide

AGP has earned the trust of more than 1.000 clients around the world, protecting heads of state, ministers, soldiers, leaders in the private and corporate sectors, and even Popes.

AGP has earned the trust of more than 1.000 clients around the world, protecting heads of state, ministers, soldiers, leaders in the private and corporate sectors, and even Popes.

AGP sGlass solutions for military vehicles have been qualified for survivability performance and durability in accordance with NATO and MIL-STD standards. AGP products have been audited and tested by Armed Forces around the globe.

By combining decades of experience with a strategic global presence, AGP sGlass will exceed your expectations.

Our offering focuses on the development and improvement of products for defense and safety applications with the utmost consideration for survivability of platforms utilized by the armed forces.

AGP sGlass is also able to address custom ballistic requirements, which include designing transparent armor systems that maintain their ballistic integrity in extreme environments and against multi-hit threats.

Transparent armor for military purposes qualified for extreme environmental conditions including ballistic qualification at high and low temperatures after 12 and 24 hours of pre-conditioning.

AGP´s high performance options incorporate the latest technologies and materials that keep the ballistic integrity of the transparent armor, thus providing complete ballistic protection in the harshest hot or cold environment conditions. Compositions for differente ballistic levels are tested in temperatures ranging from -50 to +70°C and different soak times.

Lightweight transparent armor that is produced with special materials and thickness of the glass, while maintaining its ballistic performance.

Newer technologies will use glass ceramics and transparent ceramics to achieve remarkable reduction of weight.

AGP Dura is the newest family of bullet-resistant glass with special compositions resistant to chemical reactions and scratches on the inner side of the glass. AGP Dura compositions have been designed for superior durability and enhanced lifespan.

Standard combination of glass and plycarbonate spall shield.

New polymers that enhance the resistance against scratches.

ultrathin glass cover for enhanced resistance against scratches.

A formula without polycarbonate that provides outstanding durability.

Turn-key solutions, providing best-in-class support from development up to the delivery. Build-to print and design-build capability, including project development in AutoCAD, Rhinoceros and Inventor, Structural Analysis and Finite Element Modeling with ANSYS.

The process is supported by a high level of multidisciplinary professionals in Engineering, Quality Assurance, Manufacturing and Logistics.

Co-design capabilities for enhanced durability of the transparent armor while supplying a turn-key solution for your platform. Design of specialized packaging for safe transportation and storage. Environmental qualification testing of complete assemblies on request.

AGP designs heating systems including the heating mat and temperature controllers for military vehicles for deicing and defogging purposes.

State-of-the-art environmental qualification laboratories for Light Transmission / Temperature Shock / Solar Radiation / Vibration / Humidity / Shock / Sand and Dust / Ballistic protection / Abrasion.

Products compliant to environmental qualification testing in accordance with MIL-STD-810, AECTP-500 and TL2350-006.

Production and quality records fully traceable for each piece.

Quality acceptance criteria based on ATPD 2352, TL2350, ANSI Z.26, ASTM F428.